Wrought Ironwork:

If you are building an upscale home there may be a need for wrought iron looking appurtenances. Most so-called wrought iron accessories are in reality made from mild steel, since wrought iron is rarely used any longer. Some items you may want to order that are constructed of iron will be: exterior upper balconies (Photo 29, Ch. 19) and interior stair and balcony rails (Photo 14, Ch. 13) or maybe some outside fencing (Photo 27, Ch. 18).You will probably learn that subcontractors in your area, who will provide ironwork, specialize solely in the fabrication and installation work of this craft. The installing subcontractor is usually also the manufacturer of the assembled iron pieces placed on the job. He will have a shop with welding, cutting, polishing, and painting capabilities. There is considerable markup in the work as well as skill and plant requirements needed, so that companies can be profitable by doing ironwork alone. This sub is no less critical as an independent hire than other companies or people with whom you contract, so verify his insurance, and get a subcontract agreement as described in Chapter 5. Any one person or company who is not directly employed by you on a regular basis should sign a separate subcontract agreement and maintain their own insurance coverage if possible.

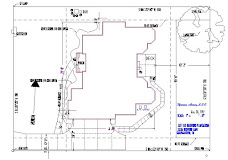

You will need to meet the iron salesman very early in mid-framing before drywall has been installed. This is because blocking and supports may need to be furnished in the wall structure for hanging balconies or to attach the heavy wall rails. There is also considerable lead time involved with iron work that requires a month or more advance notice. Some means of locating these support blocks will be required at the time of installation, so prepare a diagram or drawing with dimensions of the positions and sizes of the blocks for later use. Take a photo as well. After the drywall and stair treads have been completed the iron salesman will have to return to finalize his dimensioning to accurately fit the finish work.

There are many variations of balusters, railing styles, and paint finishes that are available for ironwork. This will require a trip to the showroom or a list of previous jobs you can visit that the iron sub has completed, so that you can make up your mind about colors and architectural forms well in advance of ordering. It would be wise to get a sketch along with your quotation from the wrought iron company to avoid any confusion later. If the company is too busy to produce these at the time, you should draw your own rough sketches, dimensioned to give a fair representation of the look you want with notes describing styles and colors. Email or hand deliver these to the sub soon after the quote is given. This will document the design upon which the price was based and prevent debate later. The cost of ironwork is considerable enough to merit the extra effort on your part.

After one installation an iron subcontractor asked me for payment well in excess of his original estimated price. I questioned this, and he replied that his cost were higher than he figured. I told him that I had turned down other bids to accept his and could have gotten the work done for much less than he was now asking. I continued that if I didn't want to know the price in advance, I would have forgone the quotation process, and just told him to build it, and charge whatever he wanted later. He wanted me to absorb the cost of his mistake.

This iron work sub then attempted to manipulate the situation with guilt, by saying, “You are getting a really great price on that, my friend.” You will be confronted with this tactic repeatedly, so keep these arguments in mind for your rebuttals. Subcontractors are supposedly experts in pricing their own work; errors are their cost of doing business. Perhaps a contractor would be more suited for another profession if he does not know what his costs are before hand. This is the way the free market weeds out incompetence and overpricing.

No comments:

Post a Comment