Fireplace And Chimney:

Framing The Fireplace Enclosure:

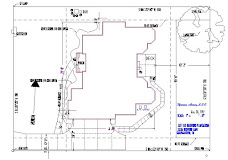

The framer will build a chimney chase and enclosure (see Chapter 8) for the direct-vent or ventless firebox if it is a prefabricated metal one and not brick. You will have to call the supplier for the rough opening dimensions at the face of the firebox, and be sure to add to the vertical dimension for any raised hearth. Give these dimensions to the framer. Also be sure the chase dimensions will clear the chimney by 2” on all sides even though rated for zero clearance. Many prefabricated fireplace manufacturers only require a zero or two-inch clearance to combustibles, like wood studs. Try 25 gage interior steel studs to perhaps save some money over wood, and to allow zero space around a firebox. Our floorplans usually called for a seven-foot wide face on the chase that allowed for a tile surround and mantel legs on each side of the opening for up to a forty-two inch model firebox.Setting the fireplace in an outside corner seems to be a desirable design feature, since it allows a view out the windows from the same vantage point (the sofa,) gives easy access for outside air ducts, and facilitates efficient furniture placement. The windows, TV, and fireplace can all be seen from the area's seating arrangement with this design scheme, as shown in Photo 13. The third focal point from the viewing location is the TV, so try to group these three in your room design.

Chapter 8 carries more discussion on masonry work for fireplaces. You will need to consult a brick yard for components used for a masonry fireplace. Be sure to buy a log starter with other iron implements to avoid forgetting this later, but the plumber, not the brick layer, will be installing it.

Brick fireplaces are heavy, massive monuments that require substantial foundation support and are not easy to remove, like prefabricated fireplaces, if you later decide you made an error in location. It is excessive overkill to construct a masonry fireplace and chimney just to insert a gas log set. Only build a brick fireplace to burn wood. The gas starter (perforated pipe set below a log grate with a valve) may be installed by a licensed company. In Tennessee a plumber needed a separate license other than plumbing to install gas piping and equipment for a fireplace.

Photo 13: Note corner

fireplace, window, and TV accommodate one viewing direction.

Observe 12 ft. vaulted ceiling, using traditional 8 ft. exterior

stud wall.

Photo 13: Note corner

fireplace, window, and TV accommodate one viewing direction.

Observe 12 ft. vaulted ceiling, using traditional 8 ft. exterior

stud wall.The trim sub can build a mantel (see Photo 13 & Chapter 15, Photo 21 ) on site and save a great deal of expense over a manufactured model. Chapter 15 contains more information about the mantel and bill of materials.

After the chimney chase is constructed by the framer and the roof is decked, prior to installing sheetrock, you should call for installation of a metal firebox and chimney. The fireplace supplier, usually required to be licensed with a permit for your project, will normally have crews who will do the installation also. A diligent builder will have gotten a price on the installation well in advance. The gas logs or starter for the prefab fireplace will be delivered by the supplier much later in construction once the gas is turned on.

Other Fireplace Accessories:

Call the plumber to roughin the gas lines and run a capped gas

supply line to the firebox at this time, before the walls are closed.

This requires a separate permit that the plumber must be licensed to

pull. Show the plumber where to put the manual wall shut-off valve.

You may want an electric wall switch or handheld remote that controls

an automatic gas valve for gas logs, both provided by the fireplace

supplier. Tell the installer and the plumber where to place their

accessories away from the mantel and surround, or you will find the

valve and switch have been placed where your tile surround and mantel

leg appear. A two-foot clearance to the edge of the firebox rough

opening is usually ample.

The framer will have to insert a firestop that the chimney will penetrate at the attic or next floor plane, consisting of plywood of thickness rated to retard flame spread for the code required period. Usually two layers of 1/2” plywood laid horizontally provide the required fire rating, but verify this.

If you want a raised hearth you will have to tell the fireplace supplier to set the firebox on eight inch or twelve inch concrete blocks. This also affords a more prominent mantel and elevated firebox viewing angle. He will strap the unit to the framed opening and may run a four-inch pipe to a through-the-wall vent cap for outside makeup air to the firebox, discussed earlier in this chapter. This pipe will be always opened to the outside and may need insulating to prevent condensation on its surface in winter. This is rarely done, however, since the minor drip usually evaporates readily.

Types of Fireplaces:

If you spec (specify) a direct-vent fireplace, a small flue will be required through the wall or the roof. These are factory-built, metal prefabricated fireboxes that contain gas logs and sit on the concrete floor slab or elevated on cinder blocks. They do not require the more elaborate and larger flues through the roof that a conventional gas fireplace needs, because they burn more efficiently. Propane can be used instead of natural gas, however this LP (liquid petroleum) gas is heavier than air, and creates a hazard when igniting the gas logs. This is because LP gas can possibly linger at the floor level in an invisible gas cloud, unknown to the inhabitants,. Natural gas is lighter than air and dissipates quickly into the atmosphere and therefore avoids the hazard.An even more efficient gas log, prefabricated fireplace is available in the ventless model.

(continued in book Working for Subs)

No comments:

Post a Comment