The below is an excerpt from a book of 309 pages, 19 Chapters, 10 Appendices

- (See Amazon for URL link to preview, following this.)

CHAPTER 8 Framing,

Roofing & Masonry:

The major

activity of this chapter is framing. However, brick work follows

naturally in the construction schedule, and is discussed later in the

chapter. Other veneers can often be installed by the framing

subcontractor, like lap siding or board and batten.

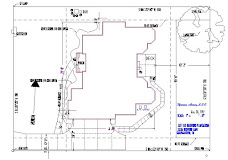

Detailed Schedule - Part E* [part of a total schedule to build a home]

-

hire

framer. Fill out I-9 formsi,

get Social Security Number, W-4’s, address, phone, I-15 form for

workman comp. (TN) / certificate of insurance, email address.

- (See

Appendix E, Lumber Order.) Install black plastic sill skirt flashing

(TN). Caulk or use sill sealer under bottom plates. Slab insulation

if required by energy code.

- Give the

cornice details to framer. Count chimneys to be built for sub.

- Order

lumber and sheathing through top plates (after 1st of

month.) Reuse 2x8 forms as headers. Install sill sealer?

- Order TJM

joist package if desired, 2x4 utility grade lumber for plates &

braces, a roll of Seismic & hurricane straps if in a

natural-Disaster prone state.

- Order

rafter /truss package.

- Order

windows (see Chapter 9) and exterior doors.

- Order

cornice (soffit vents & louvers) –wood window arches

- Order

prefab fireplace installed (Chapter 11.)

- Build

whirlpool platform for drop-in type.

- Order roof

decking (or 1x8 no. 4 spruce roof deck planks), plywood clips, &

siding. Install louver dormers. Ask if framer needs more nails

ordered.

- Install

skylight curb & flashing & fireplace chimney chase (Chapter

11.)

- Foam

insulation or board at slab edge.

- Clean

interior and throw into yard at regular intervals.

- SLAB

ENGINEER’S LETTER needed, and due about now -verify received.

- Build

shutters for painter and trim subcontractors (see Chapter 16.)

- Any

painting required? Prime cornice, siding, louvers, plywood corners,

and gables.

- Hire

roofer (verify liability & workman’s comp. Insurance.)

Install copper over dormer roof (range hood? Chimney cap?)

- Hold

off roof below stucco interface, just felt temporarily. Provide

flashing for stucco.

- Order

roofing (1 bundle/sheet of plywood), FELT (400 sqft/roll), and

90#rolls (for valleys); hip & ridge shingles, skylights &

dormer step flashing, & valley flashing rolls.

- Get

quotes: Hardwood / tile floor (Chap. 15), fireplace surround, tile

countertops, wall & shower enclosure.

- Bricklayer

/ Stonemason (leave gas starter for plumber.) Order brick, flue cap,

any stone, sand, mortar, quoins for windows.

- Order

brick for fence posts & mailbox (or steel mailbox,) cast iron

(C.I.) crawlspace grilles, ash clean out, flue liner, C.I. damper,

lintel, 7 bags mortar/1000 brick, and chimney cap flashing. Get

brick wall tie inspection.

- Pour

fencepost footer & condenser pad (does HVAC sub provide?) after

brick delivery.

- Call-before-Dig

___(phone no.)__ 72 hr. in advance -good for 15 subsequent

days.

- LG&W

to mark gas and electric meter location on inside walls.

- Plumbing

top-out gas to front lanterns.

- Call-before-Dig

___(phone no.)__ 72 hr. in advance -good for 15 subsequent

days.

- Order

cabinets (6 week lead time,) pulls & hinges, 8”deep composite

sink, 32”high vanity, tile/granite tops?

*Detailed Schedule – Part E in this chapter continues

the sequence of construction tasks following Part D in Chapter 6. See

Appendix B for the complete Detailed Schedule. Dimensions and amounts

are based on codes in Tennessee, Colorado, and Florida, local

requirements, and the Uniform Building Code that change annually in

some cases, so verify all in this book before acting on them.

Lumber

You as the

builder must be diligent when ordering lumber. Many builders order an

entire package once the slab is completed, consisting of plates,

studs, rafters, sheathing, and even siding, all delivered at once.

This may result in waste, weathering, inefficiency, vandalism, and

theft more often than not. If you can time your order until after the

beginning of the lumberyard's monthly billing cycle, payment can

often be delayed on this large expenditure until the tenth of the

following month, aiding cash flow. Lumberyards often offer a discount

of up to two percent if paid by the tenth of the month (

2 percent

10, net 30 in accounting parlance,) otherwise the total net

amount is due within thirty days.

A builder can

give a set of plans to the lumberyard, and they will do a detailed

take-off of all materials that they supply, saving the trouble and

time of this work. However, the lumberyard will normally over supply

many components, since they are in the business of selling the goods

they quoted, and they also do not want to be accused of holding up

the job due to shortages. You will be told that they will pick up any

excess overages at the end of the job, however, by that time

excessive leftovers are missing or destroyed due to weather and

mishandling on the job and not fit for return. If you do give your

plan to a lumber company for a quotation you should also give them

the job even if you do the ordering yourself, since the take-off is

quite a bit of work. So, prior to asking someone to do an extensive

plan quotation, do some pricing of items at various local companies

first. For instance, get the price of a 2x4 stud and a 2x8, etc. and

compare other samplings of wares. After that take your plans to only

one company to be evaluated.

The lumber

company's quote will help you verify your count of materials and is a

useful tool as well. We always did our own take-offs, since this

forced us to do an analysis of the design as well, when counting the

elements making up the structure. We also saved a good deal of money

by keeping our orders closer to an accurate amount with less waste,

when we did our own counts and then compared to the lumber yard.

Be sure to

consult with your framing subcontractor prior to ordering as to what

he will need. A small crew may take a week and a half to two weeks

just to erect the first floor walls and joists. In the meantime they

will be tripping over excess materials on the site, which are usually

placed in the most obstructive spot, right in front of the structure,

as that is the most convenient delivery spot. This is also the

easiest place for thieves to back up their pickup truck and abscond

with your precious materials.

As the

uninstalled lumber and sheathing lays around the site waiting for its

rightful place in the superstructure, it is all the while warping or

curling due to being unsupported at several points. This is

exacerbated and prolonged if there is precipitation. The framer will

separate the deliveries into manageable stacks of about the same

sizes. At the end of each day you will find much of the lumber laying

haphazardly around the site, unsupported and sitting in the mud and

dirt. I used to visit the job periodically and spend time stacking

lumber on ground skids made from scrap two-by cuttings, placed about

four feet apart. This helped the framer remain organized, and saved

my lumber from deterioration, warping, and bowing. You would expect

your framer to do the sorting and stacking for his own efficiency,

but that will not usually be the case.

At the same

time you or your trash subcontractor can toss small pieces of lumber

with nails exposed into various small piles away from the house. This

will serve as a safety measure and make your job site more

accessible. Your trash sub can gather and remove the piles quickly.

Some small two-by scrap pieces can be used for bridging, fire

blocking, or for nailing blocks behind the drywall toward the end of

framing. This avoids cutting up long lengths of boards for piecemeal

work. For this reason it is a good idea to keep a bit of trash on the

job longer than a normal time. In the winter your subs will burn your

lumber scrap for warmth, and when you aren't around they will cut up

your lumber and burn that rather than pay for their own salamander

propane heating. This may be avoided by ordering a face cord or so of

firewood. During the framing process you or your trash subcontractor

will need to make frequent visits to clean the interior floor slab,

so that people do not trip over all the debris that continually piles

up each day.

You may want to

add nailing blocks after the framer has left the job, including

behind towel bars, grab bars, toilet paper rollers, wall light

sconces, curtain rods, stair skirts and handrails, or supports for

closet rod ends. These block-outs provide a solid support for these

accessories behind the future drywall, and waiting on the sub to

return is inefficient.

We once had a

guy just show up and start clearing away our scrap lumber without

even consulting us. Later he asked to be paid for trash work that we

did not even request. This was wrong of him in many ways. First of

all, our insurance would not have covered him, since he was working

on our site without permission. Secondly, we lost much of the useful

small lumber pieces that could have been used in the framer's work

instead of having to cut up full boards to make braces, blocks, etc.

Third, this guy created animosity between us and himself by presuming

that we owed him for something we did not even want.

This builder

prefers to order materials in phases (see Appendix E – Lumber

Order,) and most lumber companies do not bill additionally for

deliveries as long as you plan to order the entire package from them.

Break the loads into manageable sizes based on use within a week to a

week and a half. This means you can order the wall-framing package

(through top plates) and perhaps the joists and part of the sheathing

for corner bracing in the first delivery. The lumber companies we

used could get an order out the next morning if placed before noon.

Visit the construction site daily more than once, and near the

appropriate time discuss with the framer when to order second floor

or first floor ceiling joists and the remainder of the sheathing.

A separate

order can include the second floor wall package and ceiling joists.

The roof rafter order should be delayed until nearing the completion

of all exterior wall sheathing. There is no need to have these

members stacked idly for a week or two before installation,

deteriorating. Place the cornice and siding order last, since this

material needs to remain straight and will become warped &

weather beaten laying around the site too long. Order attic

ventilation (if not a cool roof / unvented attic) louvers and soffit

vents at the time of the cornice order. There will also be several

small weekly deliveries of 2 x 4’s and other miscellaneous pieces

that have run short.

Order seismic

straps and other hardware with the first order of lumber, since the

framer will need them once the top plates are installed. These are

sometimes called hurricane straps, since they perform a similar

function in high winds as they do in earthquakes. This is to mitigate

e effect of racking of the structure, rather the sideways deflection

of the members at different degrees, which can break apart weak

connectors holding building elements together. You will find that the

strapping requirements vary state by state due to differing

conditions in each local, so check your codes. Tennessee has

earthquake influences, and Florida hurricane winds.

Engineered

lumber, like truss joists or I-[shaped]

joists, should be ordered as early as possible, since they have a

long lead time before arrival on the job. This could take six weeks

or more. Verify whether your lumber yard will hold them and ship to

the job on the day they are needed. I once had a one-and-half story

home where I mixed second floor joist types between engineered and

normal two-by joists. This was done much to the dismay of the local

lumber supplier, who wanted to provide the entire job in expensive

engineered lumber. Our solution was possible, because much of the

upper level was low attic, and elsewhere second floor walls needed

support within in the ceiling below without bearing walls on the

first floor.

Order windows

and exterior doors about the same time as you order your first lumber

delivery, since they usually have a long lead time. Most lumber

companies will hold these until you request delivery, but will order

them early to have them in stock when you call for them. See Chapter

9 for more on this subject. You should check windows and doors for

level and plumb and shim them as needed after the framer has placed

them and before the bricklayer begins encasing their brickmold.

Almost all of our jobs had the fenestration installed improperly

after the framer had considered it complete. If you can get the

framer back to shim his work in a timely manner it will be unusual.

We used to ask

the framing contractor to install a 36” inside door between the

house and the garage, even though they did not normally do this in

Tennessee by custom. The trim carpenter did it. We ordered that door

with the windows, the front, and the rear door package, because that

particular door similarly had exterior trim with weatherstripping,

threshold, and brick mold. This way we could close up the house early

to prevent intruders (usually teenagers partying or curious

neighbors) after the framing. Since drywall normally is installed on

the inside of the garage before this door, we had to have the framer

space it with small pieces of blackboard behind the brickmold as a

temporary shim where drywall would normally lie. This is an example

of the problems incurred by attempting to do things in innovative

ways, since it is often easier to merely go with the local tradition

and avoid conflicts.

Order any

trusses you will need for the roof at least two months in advance.

There are truss manufacturing companies that will do a truss diagram

for you, and engineer these to fit your project. There is normally no

fee for this design if you order from that company.

When each

lumber order arrives or any other materials, the builder should

always plan to be at the job site soon thereafter to count the load.

I occasionally found deliveries that did not match the purchase

order. Oddly, these were always short (of a lesser count) and never

in excess in my favor -go figure.

....(continued in book)

i

See web page http://www.uscis.gov/files/form/i-9.pdf ; Dept. of

Homeland Security employment eligibility for work in the United

States. [last accessed 6/12/13]

------------------------------------------------------------------------

To preview the book that Geoff wrote cut and paste the following link to your browser: https://www.createspace.com/Preview/1194783

To order the 306 page book cut and paste the following link to your browser:

https://www.createspace.com/6118813

-----------------------------------------------------------------------